Free Shipping on Order Over $50

Anything Under $50 Flat Fee of $9.99

Track Your Order

Free Shipping on Order Over $50

Anything Under $50 Flat Fee of $9.99

Track Your Order

Free Shipping on Order Over $50

Anything Under $50 Flat Fee of $9.99

Track Your Order

Free Shipping on Order Over $50

Anything Under $50 Flat Fee of $9.99

Track Your Order

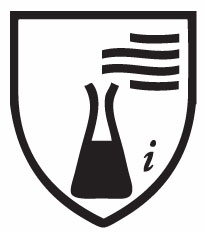

The information “i” shown in this pictogram indicates that the gloves resistance to chemicals will be shown on a separate reference sheet.

For gloves that cannot resist some chemicals for more than the required 30 minutes.

The ‘Micro-organism’ pictogram is to show when the glove conforms to at least a performance of less than 60 minutes (level 2) for the Penetration test.

| LETTER | CHEMICAL |

|---|---|

| A | Methanol |

| B | Acetone |

| C | Acetonitrile |

| D | Dichloromethane |

| F | Toluene |

| G | Diethylamine |

| H | Tetrahydrofurane |

| I | Ethyl Acetate |

| J | n-Heptane |

| K | Sodium Hydroxide 40% |

| L | Sulphuric Acid 96% |

There are more than 15,000 chemicals commonly used commercially and industrially worldwide, this is why EN 374 approved and tested chemicals are so important. These 12 chemicals are carefully tested and selected to give the best overview of a glove’s chemical performance.

A glove must not have a permeation breakthrough when immersed for a minimum of 30 minutes in one of the 12 chemicals (shown to the left) to be awarded the adjacent letter

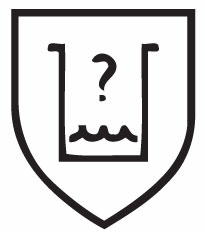

For level 3 of conductive heat the glove’s inside material must manage 350°C heat for 15 seconds before the material exceeds 35°C from ambient temperature of 25°C

What is HACCP? A developed system designed to identify and minimise points of failure. HACCP is also used as an international food safety certification for a variety of successful products. If a product shows the HACCP logo it is of the best food safety standards.

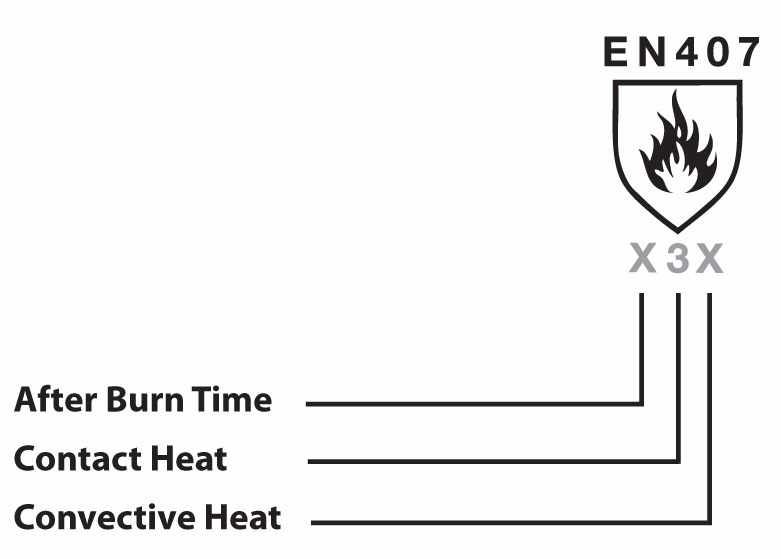

This 1-4 digit represents how many cycles of a coarse surface the glove can handle until failure

Grade 3 gloves are commonly used for handling rough edges up to 5kg. Grade 5 gloves are commonly used for broken glass or knives

The higher this 1-4 digit the more torque (Nm) a glove can take in a tearing motion.

1 = 20Nm until break 2 = 60Nm until break 3 = 100Nm until break 4 = 150Nm until break

| Test | Performance Level |

|---|---|

| Abrasion Resistance Cycles |

100 500 2000 8000 - |

| Blade Cut Resistance |

1.2 2.5 5 10 20 |

| Tear Resistance(Newtons) |

10 25 50 75 - |

| Puncture Resistance(Newtons) |

20 60 100 150 - |

Always ensure that the gloves you decide on are independently third party tested and certified.

Unless the results have come from an independent thirty party accredited test facility, then you are just taking someone’s word for it.

It is also advised that the facility is based in a country where standard enforcement is strong.